Blog

What are Auto Parts Bearings and their Importance?

Auto Parts Bearings play a crucial role in vehicle performance. Expert mechanic John Smith states, “Without quality bearings, even a well-built car can falter.” These components reduce friction and facilitate smooth movement. They are vital in various systems, from engines to wheels.

In daily operations, these bearings need regular checks. Neglected bearings can lead to severe issues, including mechanical failure. Many car owners overlook their importance. Small problems can escalate quickly, leading to costly repairs. This oversight highlights a gap in understanding.

Proper selection and maintenance of Auto Parts Bearings can enhance longevity and performance. However, many consumers choose based on price alone, often at the expense of quality. This decision can affect vehicle reliability. Awareness of this issue is essential for informed choices in the automotive industry.

Definition of Auto Parts Bearings and Their Types

Auto parts bearings are crucial components in vehicles. They minimize friction between moving parts, ensuring smooth operation. Bearings help in supporting weights and absorbing shocks. They also provide stability and control. According to a report from Grand View Research, the global automotive bearings market size was valued at over $13 billion in 2020, with expectations to grow steadily.

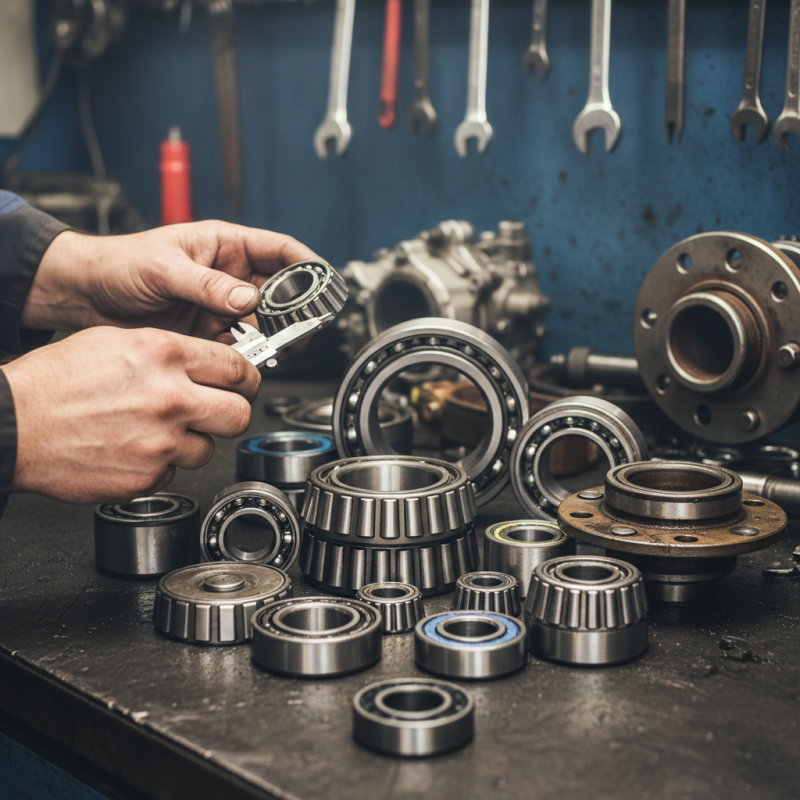

There are several types of auto parts bearings. The most common ones include Ball Bearings, roller bearings, and tapered bearings. Ball bearings are widely used in wheels and electrical motors. Roller bearings are suitable for heavy loads and can handle larger loads than ball bearings. Tapered bearings are often found in the wheel assembly of trucks and cars.

Tips: Regularly check for wear and tear on bearings. This helps to avoid costly repairs down the road. Also, consider the environment where the vehicle operates. Dust and moisture can affect bearing performance. Investing in quality bearings can save money in the long run. Remember, even the best parts can fail if not maintained properly.

Functionality of Bearings in Automotive Systems

Bearings are crucial components in automotive systems. They facilitate smooth movement by reducing friction between rotating parts. According to a report by the global market research firm, MarketsandMarkets, the automotive bearing market is expected to reach $20 billion by 2025. This reflects the undeniable significance of bearings in enhancing efficiency and performance in vehicles.

In practice, the functionality of bearings affects fuel efficiency and durability. A well-placed bearing can decrease energy loss and improve engine performance. However, improper installation or low-quality materials can lead to premature wear. Did you know that over 30% of automotive failures relate to bearing issues? Many drivers underestimate the role of these components. This oversight often leads to costly repairs and potential safety hazards.

Additionally, different types of bearings serve various automotive functions. For instance, ball bearings are commonly used in wheel systems, while roller bearings are found in transmission assemblies. Each type has specific applications and performance characteristics. Despite this knowledge, manufacturers still face challenges in optimizing bearing designs for evolving automotive technologies. The shift towards electric vehicles introduces new demands for innovative bearing solutions, highlighting a critical area for industry improvement.

Importance of Auto Parts Bearings in Automotive Systems

Importance of Bearings in Vehicle Performance and Safety

Bearings play a crucial role in vehicle performance and safety. They reduce friction between moving parts. This enhances efficiency and prolongs the life of mechanical components. Properly functioning bearings ensure smooth rotation of wheels, crankshafts, and other vital parts. Any wear and tear can lead to serious issues.

Regular maintenance is vital. Check your vehicle's bearings periodically. Look for unusual noises or vibrations. These can signal a problem. If bearings fail, the consequences may be severe. It could cause loss of control or even accidents. Ignoring minor issues can lead to bigger repairs later on.

Tips: Use high-quality lubricants for your bearings. This helps reduce friction and heat buildup. It’s also a good practice to replace bearings in pairs. This ensures balanced performance and can save costs long term. Keep an eye on your vehicle's performance. Any changes might indicate that your bearings need attention.

Common Applications of Bearings in Auto Parts

Bearings are crucial in many auto parts. They help reduce friction and wear in moving parts. This is important for the smooth operation of vehicles. You can find bearings in wheel hubs, transmissions, and engines. Each application has specific requirements. Properly functioning bearings ensure safety and efficiency.

In wheel assemblies, bearings support the weight of the vehicle. They allow the wheels to rotate smoothly. This contributes to better fuel efficiency. If bearings wear out, it can lead to costly repairs or accidents. It’s vital to monitor their condition regularly.

Tip: Check the bearing noise. Unusual sounds may indicate a problem. Addressing issues early can save money.

In transmissions, bearings ensure gears mesh smoothly. They help optimize power transfer. Poorly maintained bearings can cause gear slippage. This can lead to decreased performance. Regular inspections are essential for longevity.

Tip: Keep an eye on your vehicle’s vibration levels. Excessive vibrations could mean a bearing issue. Early detection can prevent larger problems.

Maintenance and Replacement of Bearings in Vehicles

Maintenance of auto parts bearings is crucial for vehicle longevity. Regular checks can prevent serious damage. Drivers should be aware of signs that indicate bearing issues. Noise or vibrations while driving may suggest bearing failure. If left unchecked, this can lead to costly repairs.

Replacing bearings at the right time is equally important. Many vehicle owners postpone replacements, which can worsen the problem. It's vital to follow the manufacturer's recommendations on timing. Proper tools and techniques are necessary for a successful replacement. Improper installation can lead to further complications.

A lubrication routine can extend the life of bearings. However, not every vehicle owner remembers this. Regular maintenance can be easily neglected. On the flip side, those who stay consistent with checks often avoid unexpected breakdowns. Keeping an eye on wear and tear can save money and enhance performance.

What are Auto Parts Bearings and their Importance? - Maintenance and Replacement of Bearings in Vehicles

| Bearing Type | Material | Key Features | Typical Applications | Replacement Frequency |

|---|---|---|---|---|

| Ball Bearings | Steel or ceramic | Low friction, high speed | Wheel hubs, pumps | Every 30,000 miles |

| Roller Bearings | Steel | Higher load capacity | Axles, transmissions | Every 50,000 miles |

| Tapered Bearings | Steel | Designed for axial loads | Steering columns, wheel hubs | Every 70,000 miles |

| Fluid Bearings | Metal and lubricant | Non-contact, lower wear | High-speed machinery | Every 100,000 miles |