Blog

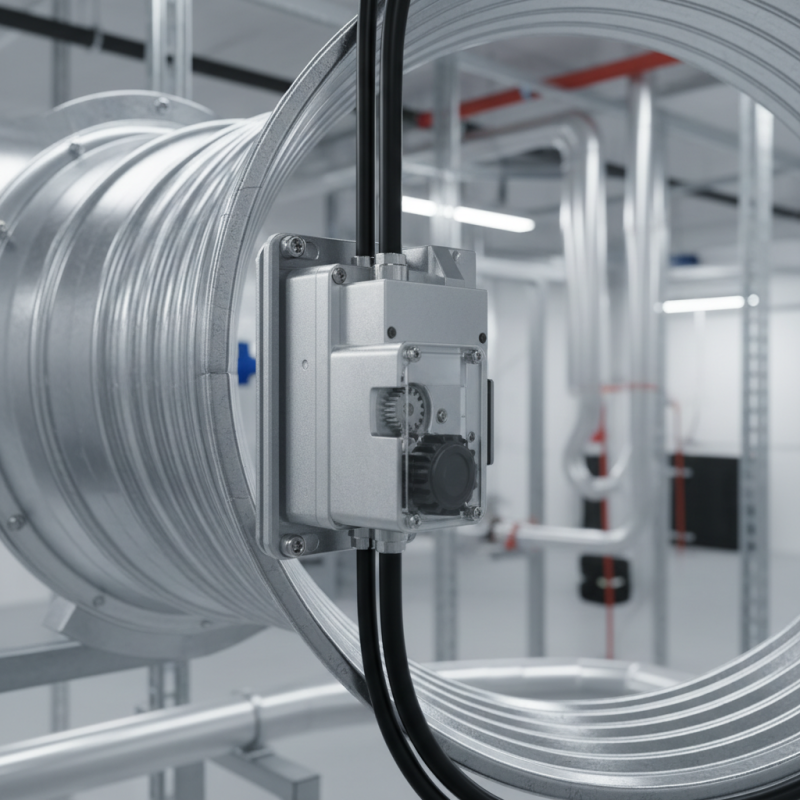

Top Tips for Choosing the Right Damper Actuator?

Choosing the right Damper Actuator can be a daunting task. Experts emphasize its importance in building efficiency. John Smith, a leading HVAC specialist, once said, “The right damper actuator can make or break your system’s performance.”

Selecting the perfect damper actuator requires careful consideration. Factors like size, type, and compatibility matter greatly. A poorly chosen actuator can lead to inefficiencies. You may end up wasting energy and money. It’s essential to understand the various options available. Misjudgment here could mean frequent replacements, costing you more.

Real-world application is vital. Each installation varies in requirements. For example, the actuator's torque must match the damper size. Understanding these specifics can enhance system functionality. Avoid overlooking details. Reflection on past choices can guide future decisions. The right actuator is not just a component; it is the heart of an efficient airflow system.

Understanding Damper Actuators and Their Importance

Damper actuators play a crucial role in HVAC systems. They control the airflow in ducts, optimizing energy efficiency. According to the U.S. Department of Energy, improper damper settings can lead to energy losses of up to 30%. This highlights the need for effective actuator selection.

When choosing a damper actuator, various factors must be considered. The size and type of the dampers directly affect performance. A mismatch can cause reduced efficiency or mechanical failures. Plus, actuator response speed is essential. A slower response time may result in inefficient climate control.

It's important to remember that not all actuators are created equal. Environmental conditions can affect performance. For example, extreme temperatures may limit functionality. According to ASHRAE, over 25% of systems face issues due to actuator failures. Regular evaluation and maintenance are critical to avoid these challenges.

Key Factors to Consider When Selecting a Damper Actuator

Choosing the right damper actuator involves several key factors. One major consideration is torque requirements. According to recent industry reports, actuators with insufficient torque can lead to poor performance. For instance, an actuator must match the size and type of damper to ensure effective airflow control.

Another critical aspect is the actuator's response time. Rapid response ensures that the damper adjusts promptly. Ideally, the actuator should have a response time of less than 1 second for optimal efficiency. This can significantly improve overall system performance. However, selecting an actuator with too fast of a response can lead to wear and tear.

Environmental conditions must also be considered. Actuators exposed to extreme temperatures or humidity risks affecting their lifespan. It's vital to analyze the specific operating conditions. Furthermore, maintenance requirements are often overlooked. Regular checks can prevent unexpected failures, as dust and debris accumulate over time. Each of these factors plays a vital role in the overall functionality of the HVAC system.

Types of Damper Actuators: What You Need to Know

When selecting a damper actuator, understanding the types available is essential. There are several options to consider, such as electric, pneumatic, and hydraulic actuators. Electric actuators are popular for their ease of use and efficiency. Pneumatic actuators rely on compressed air and can be fast and powerful. Hydraulic actuators offer high force and precision. Each type has its strengths and limitations.

Tip: Evaluate the environment where the actuator will be installed. Ensure it can withstand temperature extremes or humidity. This will help in prolonging its life and performance.

For precision tasks, consider using linear actuators. They move in a straight line, making them ideal for applications requiring specific positioning. Rotary actuators, on the other hand, excel in applications needing rotation.

Tip: Assess the size and weight of the damper and actuator. A mismatch could lead to performance issues. Keep the project’s needs in mind. Always seek to find a balance between power and control to enhance efficiency.

Top Tips for Choosing the Right Damper Actuator

| Type of Damper Actuator | Common Uses | Advantages | Disadvantages | Key Considerations |

|---|---|---|---|---|

| Electric Actuators | HVAC systems, industrial applications | Precise control, easy integration | Dependency on power supply | Check power requirements |

| Pneumatic Actuators | Process control, manufacturing | Rapid response, high force capability | Air supply needed | Ensure air supply quality |

| Hydraulic Actuators | Heavy machinery, large valves | High power density, strong operation | Complex system, potential leaks | Regular maintenance required |

| Spring Return Actuators | Safety applications, fail-safe systems | Automatic return to safe position | Limited control options | Evaluate need for fail-safe features |

| Servo Actuators | Robotics, automation systems | High precision, good speed control | Costly and requires advanced controls | Compatible control system needed |

Evaluating Performance Specifications and Requirements

When evaluating damper actuators, performance specifications are crucial. Different applications require varying torque and speed. For example, a study from the HVAC Systems Institute indicated that actuators should deliver at least 60 Nm of torque for standard systems. However, critical applications may demand more. This variation can significantly impact efficiency.

In terms of response time, the ideal actuator should operate within 2-5 seconds. An industry report highlighted that a delayed response could lead to thermal discomfort in buildings. It may also affect energy consumption. Testing these parameters is essential but often overlooked. Sometimes engineers underestimate the need for robust performance data to inform their choices.

It's not just about torque and speed. Consider the environment where the actuator will function. Dust, moisture, and temperature fluctuations can affect performance. Materials and coatings should withstand harsh conditions. Focusing solely on specifications could lead to unexpected failures. Regular evaluations are necessary to ensure long-term reliability and efficiency.

Assessing Installation and Maintenance Considerations

When selecting a damper actuator, installation and maintenance should be key considerations. Incorrect installation can lead to performance issues and increased energy costs. A recent industry survey found that nearly 30% of organizations face operational setbacks due to improper installations. Ensuring that the chosen actuator fits the existing infrastructure is crucial. It’s not just about compatibility; considering the actuator's location is also vital, as it can affect accessibility for future servicing and repairs.

Maintenance frequency plays a significant role in the longevity of damper actuators. Regular checks can prevent failures and improve efficiency. According to a study, facilities that performed bi-annual maintenance reduced actuator-related downtimes by up to 40%. However, many operators overlook this aspect. They often prioritize immediate functionality over long-term reliability.

Additionally, physical environment impacts actuator performance. Exposure to harsh conditions may necessitate more frequent inspections, which can be a challenge for some facilities. Understanding these dynamics can shape better decision-making processes and promote overall system efficiency.